174th European Study Group

with Industry

July 3rd to July 7th 2023, Felgueiras, Portugal

The 174th European Study Group with Industry will take place from July 3rd to July 7th 2023 in Portugal, at the School of Management and Technology of Polytechnic of Porto.

These meetings were created with the aim of renovating and reinforcing the links between Mathematics and Industry.

This meeting is part of the series of European Study Groups and will bring together several European experts with a large experience in this type of events.

More information on study groups and related aspects is available at the International Study Groups website, the Smith Institute and the European Consortium for Mathematics in Industry. For a fairly comprehensive list of problems and respective reports which have appeared in previous study groups see here.

Information for Companies

If you think that your company might have something to gain from discussing a problem with us, do not hesitate to contact the 174 ESGI organizers. We will be more than happy to visit you, at no cost and without any need for an immediate commitment, for an initial discussion about formulating such a problem. The confidentiality of the data provided is assured.

Almost all industrial problems have some mathematical aspect to them, although the mathematics is not always recognizable at first. Indeed, from our own experience, some of the most successful study group problems were not well-defined in mathematical terminology at the start of the study group. Study group problems can come from a wide range of industrial areas, such as Engineering, Electronics, Transport, Agriculture, Energy, Banking, Medicine. For more information on past study groups, including a description of some of the problems which have been presented at previous meetings, see Past Study Groups.

The fee for a firm to present a problem at the study group will depend on the size of the enterprise.

Companies may be present only on the first day (to expose their problems) and on the last day (for the results), but they may also stay the entire week to brainstorm ideas.

After the event, a report on each problem will be sent to the company. Optionally, one of the academics may visit the company to discuss the solution.

Information for Academics

The academic participants are a diverse group of people, including PhD students, postdoctoral fellows, and professors, with expertise in Mathematical fields such as Operations Research, Optimization, Statistics, Numerical Analysis, Computer Sciences, Physics, Finances, among others.

At the beginning of the week, a representative from each company presents their industrial problem to the participating mathematicians. The participants allocate themselves to a group, each of which works in one of the proposed problems with the industrial partner. The work will be developed in full-time over the next days. On the last day, each group will make a presentation of the results obtained and all participants share suggestions for further work.

After the study group, a report on each problem will be sent to the corresponding firm. Apart from the results obtained during the study group, this report may contain suggestions for further collaboration.

Proceedings with the technical reports produced by the participating groups will be published. Additionally a booklet containing the summaries of the results and success stories of the collaborations will be sent to potential future partners, companies and funding institutions.

Study Group Challenges

Tinamar - Tinturaria Textil, SA

Patterns of non-conformities and client’s complaints in textile dyeing

This challenge aims to discover patterns of non-conformities in textile dyeing, taking into account various variables. This challenge requires a comprehensive and analytical approach, as it involves analyzing multiple factors such as fabric types, chemical composition of dyes, temperature conditions, and processing time. Moreover, the company aims to identify correlations between these variables and the observed non-conformities and client’s complaints, such as stains, fading, or coloration failures. Unravelling these patterns entails the application of advanced data analysis techniques and machine learning, with the goal of developing a predictive model that can assist in preventing and resolving these issues, thereby optimizing the dyeing processes and ensuring the final quality of the textile pieces and client’s satisfaction.

Estofos Gémeos

Optimizing Material Parameterization for Furniture Production

The company is embarking on a new initiative to digitally transform its procedures in order to systematize the production process, optimize material usage, and provide accurate cost estimations to clients. The proposed challenge involves modelling the parameterization of materials used to produce sofas, chairs, and beds, aiming to create dynamic data sheets that streamline production processes and facilitate client budgeting. Various factors, such as material costs, dimensions, shapes, and quantities, will be considered to develop a mathematical model that accurately represents the relationships between these variables.

Ara Shoes Portuguesa, Unipessoal, Lda

Ground Planning Optimization of a shoe injection machine

Ara shoes is a shoe brand, whose production is made by their one plants, focusing on fashion and function, privileging the customers’ comfort, and standing out for the difference, with bold, thematic and evolutionary design.

One of the production processes used at ara’s factory is DIP or Direct Injection Process. An intermediate sole is made of polyurethane (PU) is injected between the out sole and the midsole of the upper which is what we call direct injection. This process makes the shoe particularly light and the midsole is comfortable for the foot. High production efficiency and low material wastage during production are two of the benefits of DIP. This is possible by machines with new standard technologies. The investment of setting up a DIP line is high in part due to the cost of the molds, therefore maximizing the overall equipment effectiveness (OEE) is extremely importance.

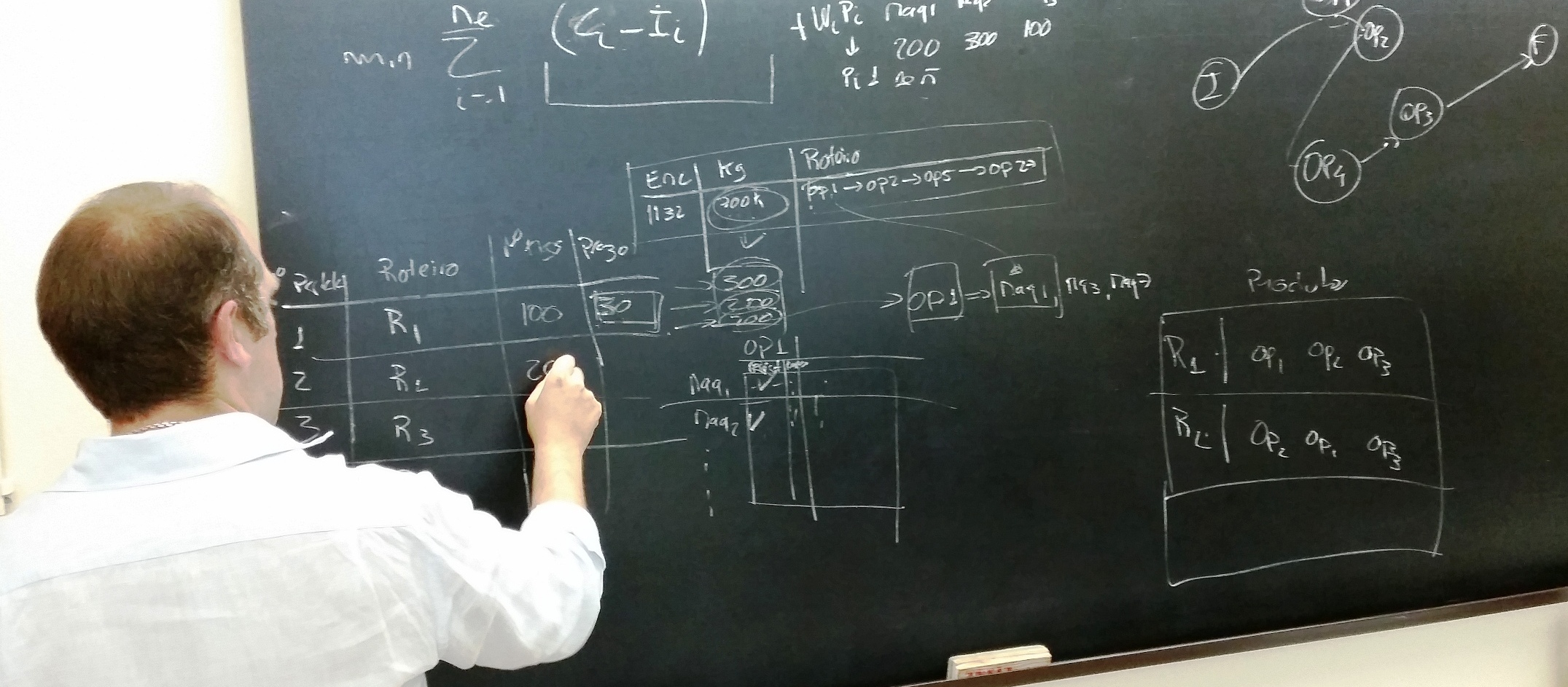

This project aims to develop a mathematical model that allows the optimal planning of a shoe injection machine, considering OEE optimization of the machine, ensuring the deadlines, guaranteeing the minimum of lost injection cycle and setting a maximum number of different articles produced at each cycle. This planning model is important for the company to reduce the time of the ground planning and machine optimization.

Softideia - Informação Automática, LDA.

Optimization of soles production

The challenge consists of the optimization of processes on a company that manufactures rubber soles, which involves the efficient management and distribution of its production orders by a set of available machines. The machines are divided into two sectors: Injection and Compression. Each machine works with one or more presses, where each press can operate with a specific number of molds. Each mold, in turn, produces a pair of soles in each production cycle.

The main question is how to distribute efficiently and effectively the production orders, taking into account the required quantities and sizes, across the available machines, considering the several assumptions. The objective is, therefore, to create a production order distribution plan that maximizes efficiency, reduces the time for configuration and change of molds and colors, and ensures that delivery dates are met.

Local Organizing Committee

Aldina Correia (chair) | CIICESI, ESTG, Politécnico do Porto

Ana Borges | CIICESI, ESTG, Politécnico do Porto

Eliana Costa e Silva | CIICESI, ESTG, Politécnico do Porto

Scientific Comittee

Ana Moura | PT-MATHS-IN & CMUP & ISEP, Politécnico do Porto

Adérito Araújo | PT-MATHS-IN & FCT-UC & LCM-CMUC

Conceição Nogueira | ESTG IPLEIRIA & CMAT UMinho

Isabel Cristina Lopes | CEOS & ISCAP, Politécnico do Porto

Manuel Cruz | LEMA & ISEP, Politécnico do Porto

Nuno Lopes | DM ISEL IPL & CEMAT – ULisboa

Paula Pascoal-Faria | ESTG - IPLEIRIA & CDRSP

Ricardo Enguiça | DM ISEL IPL & CEMAT – ULisboa

Rui Fonseca-Pinto | ESTG – IPLEIRIA

Sandra Aleixo | DM ISEL IPL & CEAUL – FC. ULisboa

Senhorinha Teixeira | ALGORITMI DPS & EENG UMINHO)

Contact us at esgi@estg.ipp.pt

Travel information

About the venue

The event will take place at Escola Superior de Tecnologia e Gestão do Politécnico do Porto (ESTG, P.PORTO) , located in Rua do Curral, Casa do Curral, Margaride 4610-156 Felgueiras, Portugal.

Porto International Airport has regular flights to the main international cities by several flag companies, as well as low cost companies. From Porto you can take the bus to the city of Felgueiras.

For detailed travel information acess: Travel Information to ESTG, P.PORTO.

Accommodation

The suggested accommodation are: B&B Hotel e Apartamentos Felgueiras, or Casa Rosa Sousa both less than 1 km from ESTG, P.PORTO.

About Felgueiras

In Felgueiras you will find the precious legacy of settlements from the Bronze Age (2nd millennium BC) and Romanization (1st – 6th centuries); the Route of the Romanesque, which includes five monuments in Felgueiras, including the Monastery of Santa Maria de Pombeiro – the largest Benedictine convent in the north of Portugal; and much heritage from the modern age to the present day. In Felgueiras you will see the most advanced entrepreneurship in the footwear, agriculture (vinho verde, kiwi and asparagus) industries, traditional craftsmanship: Terra de Sousa embroidery (also known as Lixa embroidery), Filet lace, manual rope instruments and hand shoes. It is the ideal opportunity to escape from routine, discover the land of Leonardo Coimbra, Magalhães Lemos and Nicolau Coelho, travel new routes, participate in major events, wake up with enriching experiences, taste, rest and shop. To visit Felgueiras is to live in an environment of health and well-being, to free yourself, to invigorate yourself, to have fun and relax, promoting the necessary balance of body and mind.